In the world of machining and manufacturing, precision and versatility are key factors that drive efficiency and quality. Among the many tools used in this industry, the سنبه mandrel stands out as an essential component. This unassuming yet highly versatile tool plays a crucial role in various applications, from metalworking to woodworking and beyond.

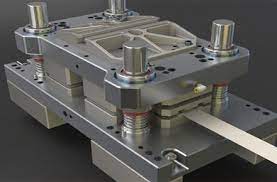

The Anatomy of a Cutting Mandrel A cutting mandrel, also known as a mandrel cutter, consists of a cylindrical body with a tapered end. It is typically made from high-quality steel or other durable materials. The tapered end of the mandrel allows for easy insertion into various workpieces, making it an ideal tool for cutting, shaping, and grinding.

Precision Cuts One of the primary advantages of using a cutting mandrel is its ability to provide precision cuts. Whether you are working on metal, wood, or other materials, the mandrel ensures that your cuts are accurate and clean. This precision is essential in industries where even a slight deviation from the desired measurements can lead to product defects and inefficiencies.

Versatility in Applications The cutting mandrel’s versatility is another aspect that makes it invaluable in machining. It can accommodate a wide range of cutting and grinding attachments, allowing it to perform multiple tasks with ease. Whether you need to trim excess material, shape a workpiece, or create intricate designs, the cutting mandrel can adapt to your needs.

Safety Features Safety is paramount in any machining process, and cutting mandrels are designed with this in mind. Many mandrels come with safety features such as locking mechanisms to secure attachments firmly in place, reducing the risk of accidents during operation. Additionally, some models have built-in guards to protect the user from flying debris.